After a long break I have finally got back to completing the Magnetic Loop Controller designed by Loftur Jonasson that I started almost two years ago now. I am using his original PCB version from June 2014 which indicates how long I have been intending to build this device!

I noticed a small SWR board kit based on the kitsandparts kit offered via the Loop Controller list by Frederik ON5IA.

I ordered a couple, but while I was waiting I checked where I had got up to with my original build.

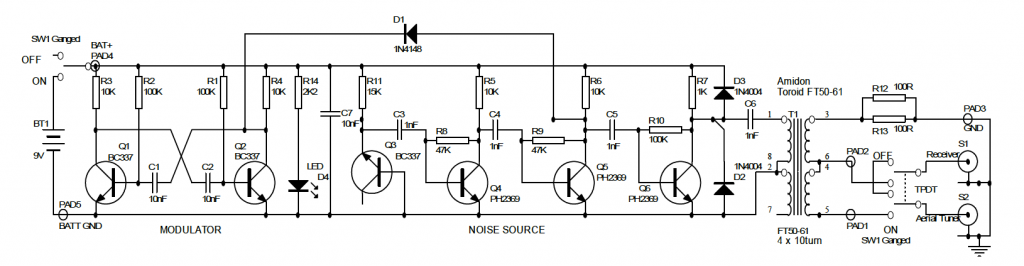

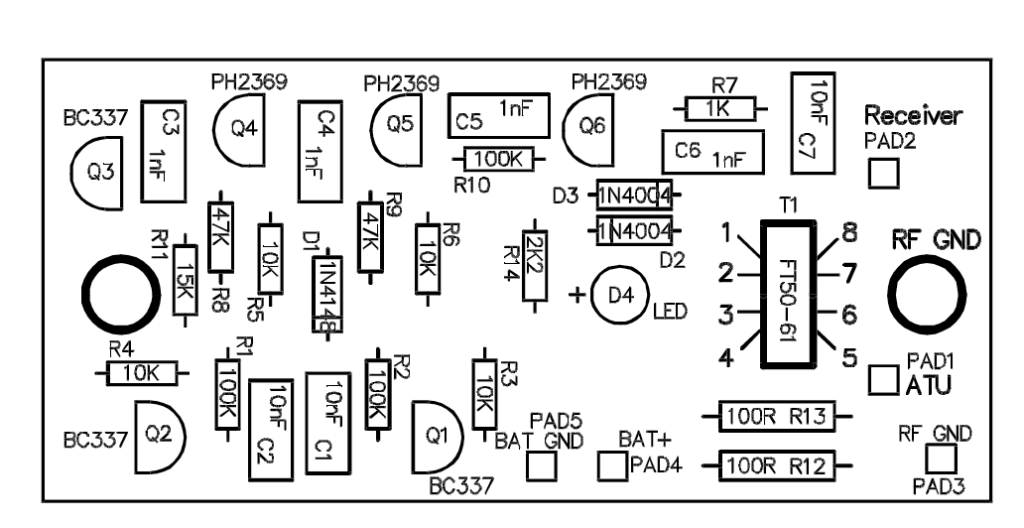

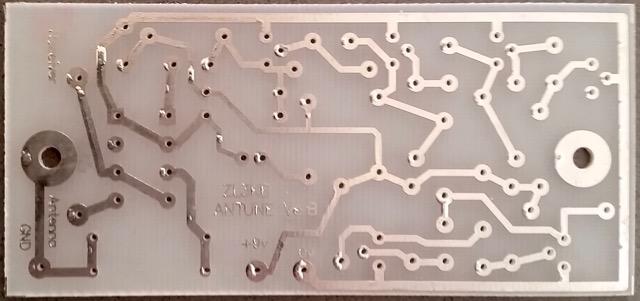

I completed my original SWR bridge board based on the kit from kitsandparts.com. I worked out I could use the same larger gauge bus wire (as used for the single turn in each ToroidCalc1 transformer) to securely and rigidly mount the SWR board to the inside of the BNC sockets. I discovered later that one of the joints to a BNC centre was intermittent, ie not actually soldered!

With the Controller apparently complete, I connected a 4-pin socket to the four wires coming from the stepper motor on the loop and attached the stepper to the VVC with the shaft couplers. I also spent quite a bit of time confirming the correct way to connect the main PCB to the SWR board, to the serial port, to the Stepper motor as well as all the other connectors and controls mounted on the front and back panels of the enclosure.

While the Teensy appears to be working as expected there was no apparent connection with the radio or the loop!!! So far the score is just one out of maybe four! (I suppose my four targets are 1. Teensy controller, 2. Serial connection with the radio, 3. Connection to the Stepper motor and 4. SWR Autotune.)

I did notice scratchy noise due to the dodgy non-joint on one of the BNC sockets. Also the Controller would occasionally just stop and reboot, especially if the enclosure was tilted slightly!

I checked continuity of the earth/-ve line. Seemed intermittent. Noticed I had used nylon stand-offs to mount the PCB. But there was a connection to the metal enclosure between the PCB ground plane via the heatsink tab of the 5 volt regulator. Decided to install metal stand offs. Needed added height of one washer to match original height for the USB socket to match the hole in the rear panel. Also confirmed that the -ve connected directly to the enclosure via the power socket mount.

Properly soldering the antenna lead eliminated the scratchy noise from the radio.

I had last installed firmware version 3.04. I updated the Arduino IDE and re-installed the Teensyduino libraries and then installed the latest version 3.08 of the Loop Controller firmware. No actual difference with connection to radio or loop.

Reading over the last couple of years of conversations on the Loop Controller Yahoo group I came across one post where someone had experienced problems connecting to their KX3. Loftur replied with a check about the way the TXD and RXD is connected to the serial lead. Mine was wired opposite to his description, as I may have confused the order on the serial header and the serial socket. Flipped the TXD and RXD connections and immediately I was able to see the frequency readout on the LCD update after a change on the KX3. Satisfying! A review of the schematic confirmed I had misread it earlier.

This was with the Elecraft K3 Auto setting on the Controller. The controller responds to changes of frequency on the KX3 but only after there is a change. And the update of the information in the frequency display feels a little laggy and as if the update periods are longish. Switching over to the polling method Elecraft K3 Poll the update is much faster and smoother. It also recognises band changes before a change in frequency. (Perhaps I need to change the KX3 setting for AutoInf back to its default). I am using a standard stereo patch cable between the serial port on the controller and the Acc1 socket on the KX3.

One step at a time! Of my four targets then, it looks like we may have achieved two!!! Now just SWR & Stepper to go.

I suppose I should be able to test the SWR board. I have a dummy load connected to the controller ANT BNC. Perhaps I could even calibrate the Power and SWR???? I have checked the ML.h file in the firmware package and read the section in the BOM and Building Instructions pdf (page 13) about the settings to enable the Power/SWR and Autotune options. #define PSWR_AUTOTUNE had been set to 0, so I set it to 1 and verified the program and re-programmed the Teensy. All pretty speedy. And it works, but because frequency ranges have not been set yet it seems to read most frequencies as out of range.

Definitely making some significant progress today!!!

Now to attack the issue with the lack of connection between the controller and the stepper motor.

I examined the solder joints of the two common mode chokes and tested them both for connection and continuity. I have also noticed that the two stepper driver chips are running very hot, way too hot to keep your finger on them for more than a touch. Also there’s probably a static discharge risk there too. Given their cost is only about $7 for these two ICs, it might be worthwhile replacing them, while taking proper antistatic precautions. It would be good if I could discover any other reason/s there is no linkage to the stepper and more importantly why they get so hot so quickly. I hooked up another NEMA 17 stepper motor directly to the board and there was again no movement, but the chips immediately heated up. With the stepper disconnected the chips still heat up.

Time to read more of the manual. That’s the only thing lacking here – a comprehensive manual pitched at dummies like me. I suspect a lot of the wisdom about using this device is waiting to be discovered in the email discussion group. I am slowly working my way backwards over the last almost 2 years I have been subscribed to the list and so far, I’m up to conversation #214 of 265 conversations, that is I have 214 to go! It would be great if you search the conversations directly from the group page… must see why I can’t do that…